Products are widely used in food, beverage, pharmaceutical, bioengineering, water treatment, daily chemical, petroleum and chemical industries.

Product introduction

Enzymolysis tank, also known as enzymolysis reactor, biological enzymolysis reactor, is a stainless steel container that provides the temperature required for enzymatic hydrolysis, adjusts the PH value and provides mixing and mixing to maintain enzyme activation and play the role of enzyme, accelerate improvement and complete the biological reaction process. Biological enzymatic hydrolysis technology is the use of appropriate biocatalysts, that is, biological enzymes, to decompose substances, accelerate the process of decomposition and transformation, and become conducive to the use of substances and the purpose of the experiment or production process. Widely used in textile dyeing and finishing, protein enzymatic transformation, biodegradation of wastewater and other fields.

Enzyme engineering is also a science and technology that uses the biocatalytic function of enzymes to transform the corresponding raw materials into useful substances and apply them to social life by means of engineering. It includes preparation of enzyme preparation, immobilization of enzyme, modification and transformation of enzyme and enzyme reactor. The application of enzyme engineering is mainly concentrated in the food industry, light industry and pharmaceutical industry.

Product structure Product structure

The main body of the enzymolysis tank is welded by three layers of stainless steel, the inner liner is made of high-quality stainless steel SUS316L, and the inner liner is polished to meet the requirements of food and pharmaceutical hygiene. The interlayer is made of SUS304 stainless steel, and the interlayer is equipped with a stainless steel baffle, which is conducive to the diversion of steam and circulating water. External welding filled stainless steel insulation, conducive to the realization of enzymatic hydrolysis process.

Enzymatic hydrolysis system mainly includes enzymatic hydrolysis tank, steam heating system, circulating cooling system, stirring system, PH regulation system, feeding system, discharge system, filtration system, cleaning system, electric control, preparation tank and other parts.

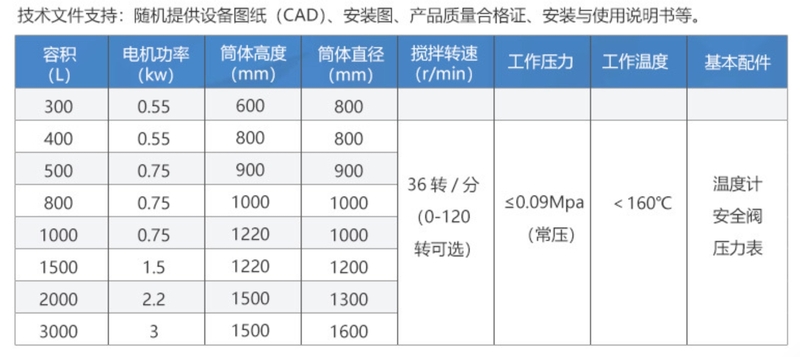

Product parameters: