Scope of application:

Widely used in confectionery, pastry, beverage, fruit juice, jam, preserves, dairy and canned food processing and brewing, wine making, pharmaceutical and daily chemical industries, as material melting, disinfection, heating, hot blanching, pre-cooking, preparation, boiling, cooking and concentration. At the same time, it is also suitable for large hotels, restaurants, hotels, guest houses, restaurants, industrial and mining enterprises, organs and troops, college and university canteens as porridge, soup, dumplings, cooking and stewed meat.

Equipment structure:

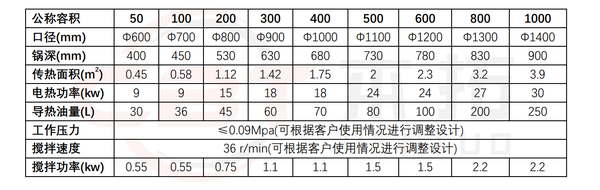

Technical parameters:

Advantages and disadvantages of heating methods

1. Gas heating: fast heating, fast cooling, adjustable frequency, uncontrollable temperature

2. Electric heating: heat conduction oil controllable temperature, adjustable frequency, uniform heating

3. Electromagnetic heating: eliminate the inertial phenomenon of heating, rapid heating and cooling, heating without dead Angle, the whole cylinder is evenly heated, and the electromagnetic coil can keep cool

4. Steam heating: the temperature is about 100 degrees Celsius, which needs to be used with the steam generation device