Plate Sterilizer Product Introduction

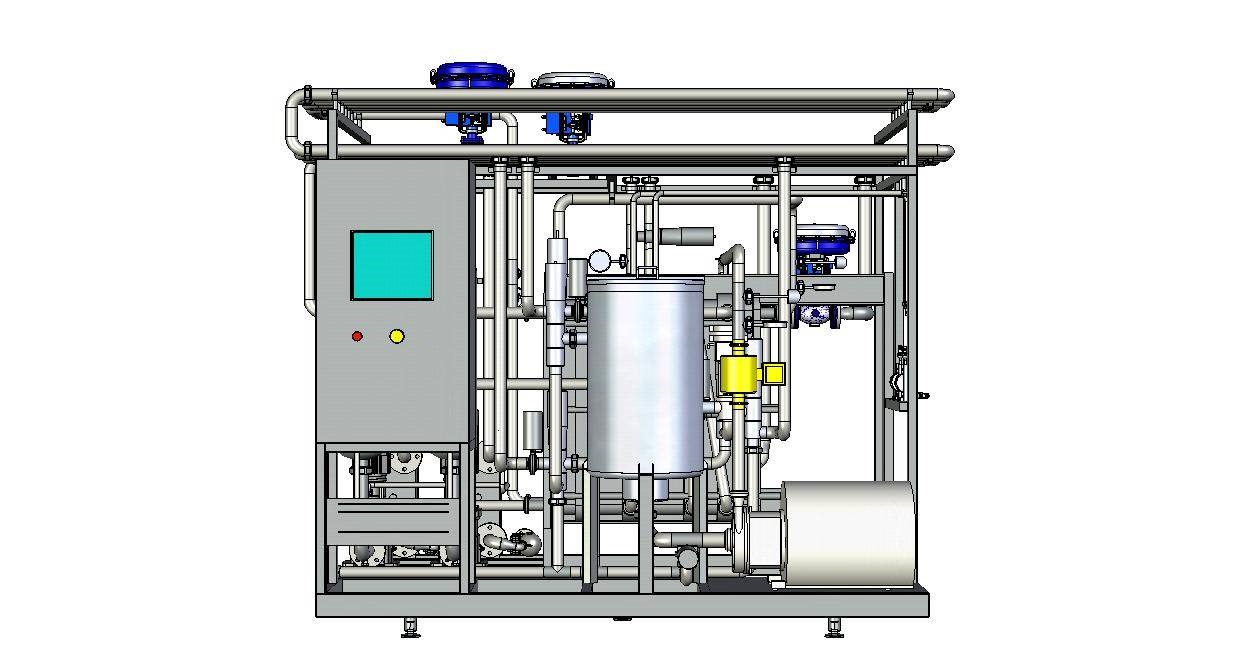

UHT plate sterilizer consists of plate heat exchanger, centrifugal sanitary pump, material balancing cylinder, hot water device (including hot water cylinder, hot water pump, water heater, steam manual adjustment valve, etc.), electrical control box, pneumatic three-way return valve (hereinafter referred to as the return valve) connecting pipeline, support frame, etc., to form a whole structural form. Plate heat exchanger according to the process requirements of the composition of preheating, homogenization (this complete set of equipment does not include homogenization), sterilization, heat preservation, cooling and other multi-stage process combinations.

Working Principle

Plate heat exchanger is the heart of the complete set of equipment, there are many pieces of peripheral edging and scarf with a sealing gasket plate, as well as the middle plate, the activities of the compression plate, heat preservation coils and other components. Plate is strictly in accordance with the process of combining the design of the sequence of diagrams arranged, stacked clamping combination. Between every two plates, the formation of the liquid channel.

There are two different liquids flowing into the plate heat exchanger:

1, the material handled (referred to as material): such as milk, etc..

2, the medium: hot water, superheated water (under a certain pressure, the water temperature is greater than 100 ℃ without boiling water), cooling water, ice water, etc..

The above two different liquids, respectively, into the plate heat exchanger adjacent to the two flow paths, each go their own way, and does not allow infiltration of the mixing, but can be constantly exchanged for heat.

Product Application

UHT plate sterilizer is widely used in the ultra-high temperature instantaneous sterilization of beverages, dairy products, fruit juices, wines and other products.

1、Milk beverage

Milk beverages are beverages made from fresh milk or dairy products as raw materials, processed by fermentation or non-fermentation. Under the condition of 135~150℃ and 2~8 s, the sterilization process of milk beverage is called ultra-high temperature instantaneous sterilization. Ultra-high-temperature sterilization of cow's milk may still contain viable spores and even microorganisms, but they are not due to microbial transformation of microorganisms in the product of individual microorganisms reproduced in large quantities and putrefaction, i.e., "commercially aseptic".

2. Fruit and Vegetable Juice Drinks

Fruit and vegetable juice drink is a variety of fruits and vegetables or their concentrated fruit juice (pulp) as raw materials, through the pretreatment, juicing, blending, sterilization, aseptic filling or hot filling and other major processes and the production of a variety of fruit and vegetable juice and its beverage products. Fruit and vegetable juice beverage sterilization process is correct or not, not only affects the preservation of the product, but also affects product quality. Fruit and vegetable juice beverage sterilization is mainly to eliminate microorganisms, prevent fruit and vegetable juice beverage deterioration and passivation of enzyme activity. Ultra-high-temperature instantaneous sterilization equipment in the application of fruit and vegetable juice drinks, that is, fruit and vegetable juice by degassing, homogenization, quickly pumped into the high-temperature instantaneous sterilizer, rapid heating to the juice temperature of 93 ± 20 ° C, maintain 15 ~ 30s, you can achieve the purpose of sterilization, the special case of 120 ° C or more to maintain 3 ~ 5s of heating sterilization.

3、Wine

Filtered beer also contains a small number of live yeast cells or stray bacteria, in order to ensure its biological stability, the need for live yeast cells or stray bacteria to kill, that is, using pasteurization. However, the pasteurization process in actual production, often longer, higher investment costs, increased production and operating costs. Now the more commonly used filling methods abroad, the former clear wine after pasteurization, that is, ultra-high temperature instantaneous sterilization. The use of ultra-high temperature instantaneous sterilization technology can maximize the freshness of the beer, the destruction of beer flavor substances is smaller, the body of the wine taste coordination, sterilization effect is more excellent.

4、Tea drinks

The PH value of tea drinks is generally 5~7, which is a low acidic beverage. The microorganisms that cause the deterioration of tea drinks are mainly bacteria, in order to ensure the safety of the beverage and storage, tea drinks must be sterilized. Due to the complexity of the components of the tea broth and the instability of the system, especially the green tea broth has the lowest redox potential and the most unstable system, so after thermal processing, especially after sterilization, its sensory quality changes greatly. After sterilization, filling with nitrogen or carbon dioxide, excluding oxygen, can stabilize the catechin substances in the tea broth.

Product features

1、Small footprint, less ancillary equipment, small investment.

2、When cleaning system, this UHT must be equipped with CIP section. Plate heat exchanger dismantling and cleaning is more troublesome.

3, due to preheating, sterilization and final cooling of the material with plate heat exchanger, so as long as the increase or decrease in the plate can be adjusted to supply heat, you can achieve different process requirements of the temperature. Therefore, it has a wide range of adaptability and flexible operation.

4, this process is for fruit juice, that is, the first preheated material, and then into the homogenizer to break up fat balls, and finally let the material into the plate heat exchanger sterilization. For other materials, the homogenizer may be placed behind the sterilization.

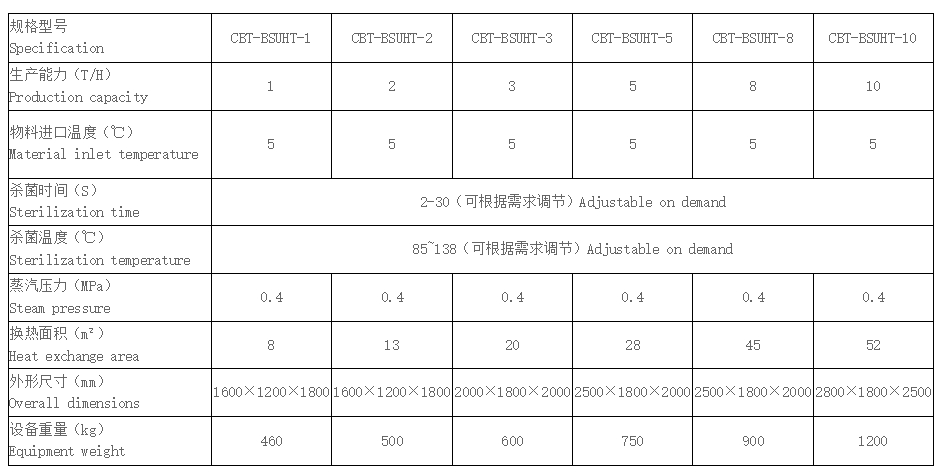

Parameter table