Working principle

Fine production, not easy to scale,especially suitable for CIP cleaning. Simple structure, easy disassembly, lownoise, high efficiency, gentle and gentle material handling, in line withhealth requirements and ensure the original flavor of the product.

Impeller unique design: impeller and shaftsleeve is one precision casting, directly installed on the motor output shaft,high strength, unique design, easy installation, high precision, to ensure theconcentricity, solve the vibration, improve the strength of the pump. Theprecision casting of the impeller and shaft sleeve solves the wear of theimpeller and wheel. The shaft sleeve is designed to deepen the inlet mouth ofthe impeller at the back end, improve the inlet characteristics of the pump,avoid cavitation, and the impeller is open, so that the cleaning is convenientwithout dead corners.

TEMPERATURE TYPE STRUCTURE

The sanitary pump is mainly composed of apump body, a pump seat and a motor, and the middle of the pump body isconnected by a quick assembly. Sanitary pump adopts smooth, rigid structure,thick wall design, in the selection of materials on the pump body, pump cover,impeller and other parts in contact with the material are all made of AISI316or AISI304 stainless steel!

The mechanical shaft seal is custom made ofhigh quality stainless steel and silicon carbide. Greatly improve the wearresistance and moisture type, extend the service life.

Scope of application

Sanitary centrifugal pump is a singlesuction, single stage, centrifugal sanitary pump, suitable for transportingmilk, beverages, wine and other liquids, is food, chemical, pharmaceutical andother industries of transportation equipment. The suction temperature can reachabout 80℃. Among them, the high head pump is suitable for pipe sterilization,yogurt temperature holding equipment, CIP cleaning and other resistancesystems.

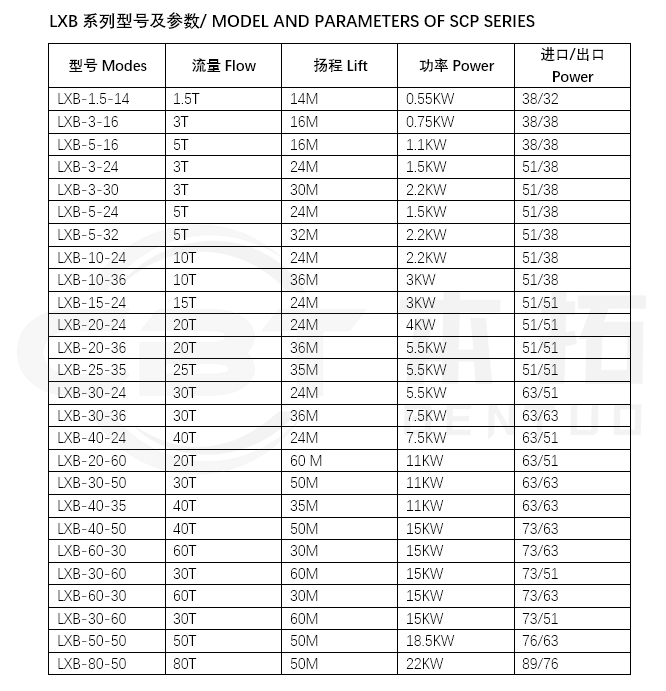

Selection list

Production shop display