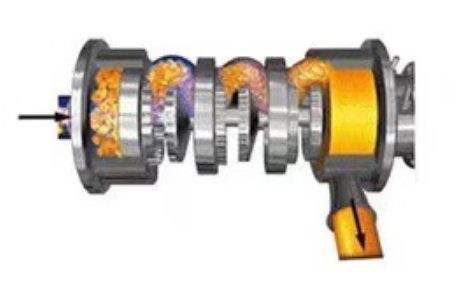

Kinetic principle

1. The product enters the shell axially.

2. Single liquid or multi-wave phases andsuspended particles are pumped through the first, second or third set oftoothed rotors/stators

3. Controlled, high-strength shear forcesare applied equally to all liquid components, regardless of product performance

4. The shear rate is constant and dependsonly on the selected rotor/stator teeth and rotor end speed

Product features:

Tubular and linear homogeneous emulsionpump is a high-performance equipment used for continuous production or cyclicprocessing of fine materials. In the narrow space of the chamber, 1-3 pairs ofmulti-layer stator, rotor and rotor rotate at high speed under the drive of themotor to produce a strong axial suction force to suck the material into thechamber. The material is dispersed, cut and emulsified in the shortest time,and the particle size distribution range is also significantly narrowed. Thus,a fine, long-term stable product can be produced.

Scope of application:

Fine chemical :(pigment, glue, sealant,resin emulsion, fungicide, coagulant)

Petrochemical industry :(lubricating oil,diesel emulsification, asphalt modification, catalyst, paraffin emulsification)

Biopharmaceutical :(injections,antibiotics, ointments, biologics, microencapsulated emulsified icing)

Coating inks :(printing ink, latex paint,architectural paint, automotive paint, coating additives)

Pesticides :(fungicides, seed coatingagents, herbicides, pesticide cream, fertilizers, biological pesticides)

Nanomaterials :(Nanomaterials disperse anddepolymerize, and react to extract nano products

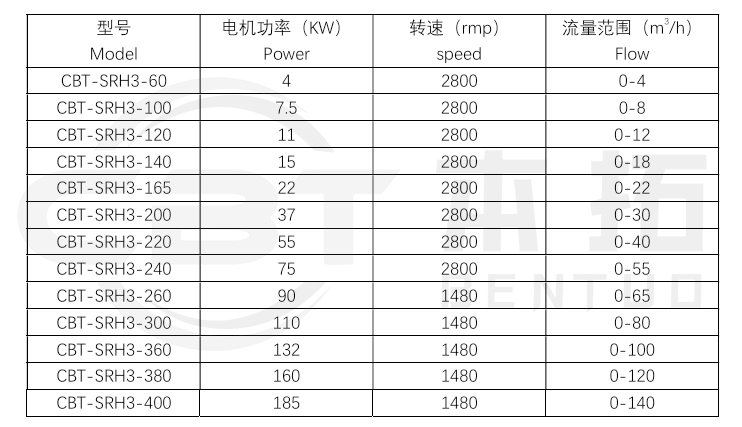

Selection parameter table

Production shop display