Refrigeration tank is usually short for direct cooled milk tank, so the refrigeration tank is mainly used for cooling, storing (storing) fresh milk or other liquid materials. It is the main supporting equipment of mechanization milking in pasture, and is more suitable for cooling

fresh milk storage in hand-milking pasture and milk collection station. The cooled raw milk protects it at its best and prevents bacteria from multiplying.

Refrigeration tank construction

1, tank body: tank inner liner, sandwich and outer envelope made of 304 stainless steel plate, xenon arc welding, precision polishing; Dirt does not accumulate easily. The inner body and shell are filled with polyurethane foam insulation material, and the outer side of the inner tank is provided with direct cold evaporation jacket plate of corresponding area.

2, mixer: by the motor, reducer and mixing device. The agitator is connected with the tank by flange, and the agitator is driven by the turbine reducer.

3, refrigeration system: refrigeration system in the refrigeration unit, direct cooling jacket plate, etc., direct cooling jacket field honeycomb jacket effect is ideal: refrigeration unit according to the needs of the cooling unit configuration of the corresponding water-cooled condenser (used when the ambient temperature is high, when not draining the cooling water) press selected with Meyulle or valley, reliable operation, energy saving and durable, ideal refrigeration effect.

Application range of refrigeration tank

Refrigeration tanks are widely used for cooling and storage of milk or other liquids in dairy, beverage, medicine and other industries.

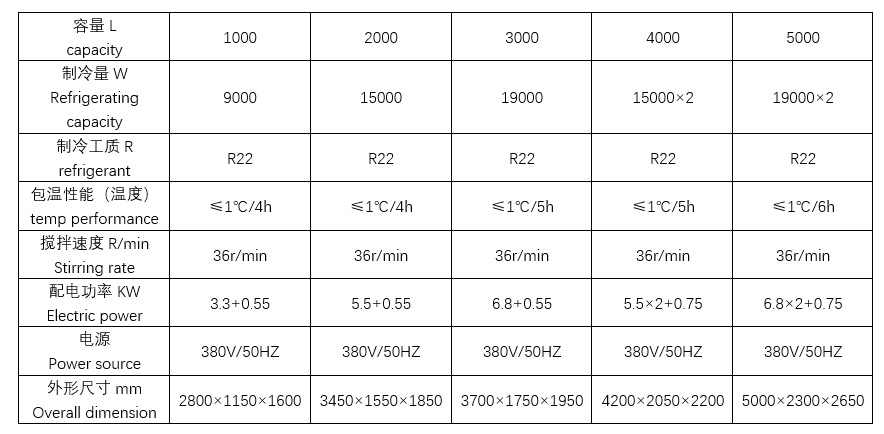

Technical parameters of refrigeration tank